egtCAM5 DOORS

egtCAM5 DOORS is the product dedicated to doors and frames design and manufacturing on numerical control machines. It consists of two parts: the first for doors design (EgtDOORCreator); the second for specific door machining. The purpose of egtCAM5 DOORS is to get a significant increase in productivity by simplifying all the stages from the design to the finished product.

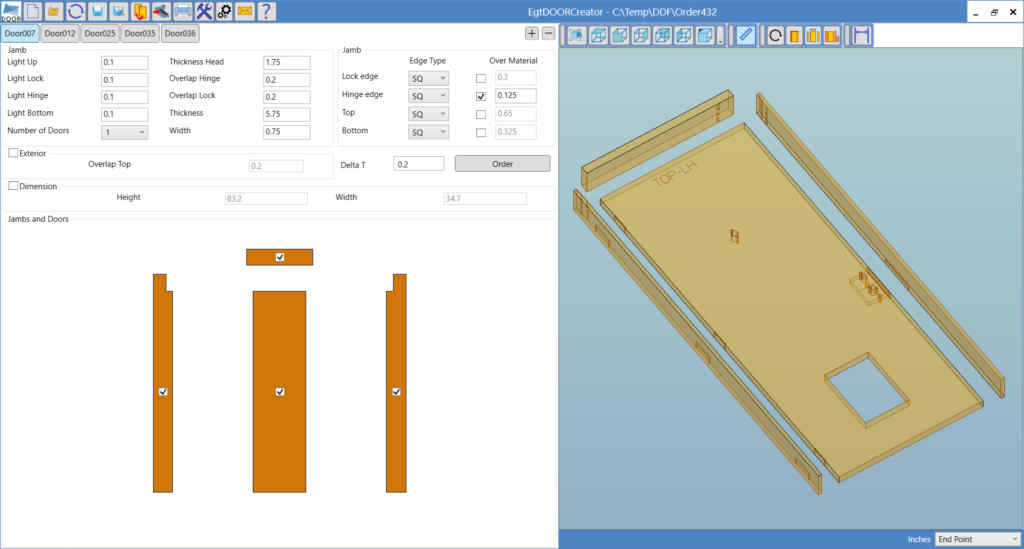

Door design EgtDOORCreation

- Parametric design of single or double doors with

or without jambs. - Possibility to define dimensions, type of opening,

shape (eg. rectangular or arched), over material. - Addition and positioning of the hardware managed

by a specific library. - Dimensioned drawing creation and printing.

- Possibility to organize production lots.

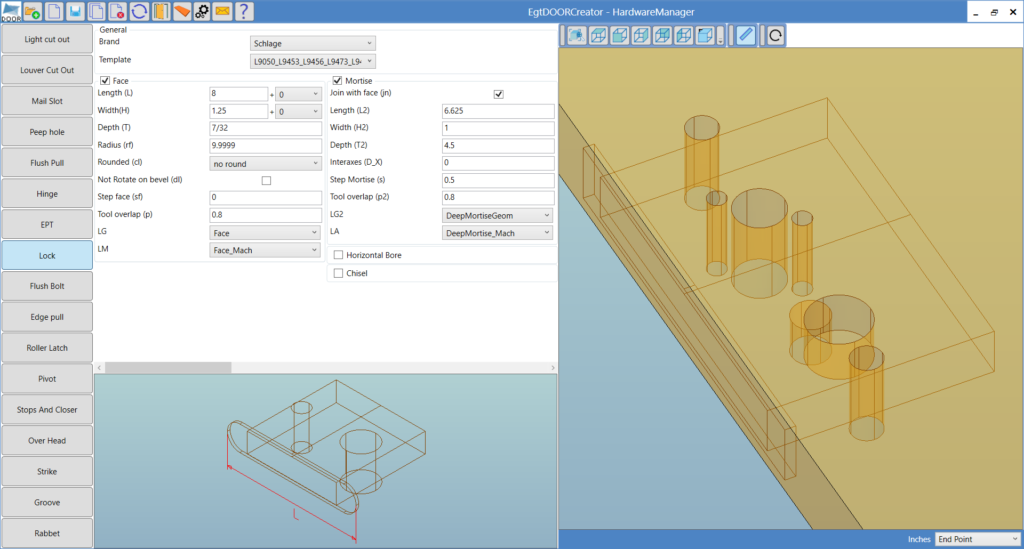

Hardware library management

- Creation and modification of hardware, grouped

by type: locks, hinges, pivots, stop and closers, roller

latches, grooves, bolts, edge pulls, flush pulls. - Creation of slots grouped by type: light cutouts,

viewers, mail slots, louver cutout. - Copy and customization of existing models.

- Archiving by brand and model.

- Managing thousands of models.

- Creation and modification of hardware, grouped

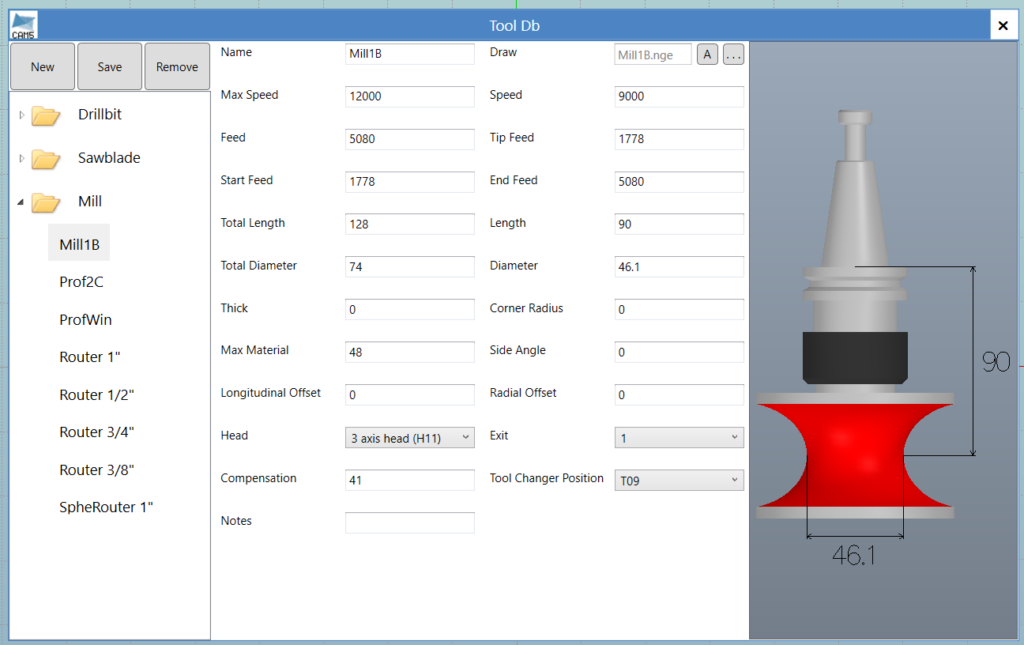

Tool libraries and machining management

- Tool library: drill bits, milling cutters, blades, chisels.

- Creation, modification and saving of tools setup.

- Machining library: drilling, milling, sawing,

contouring, pocketing.

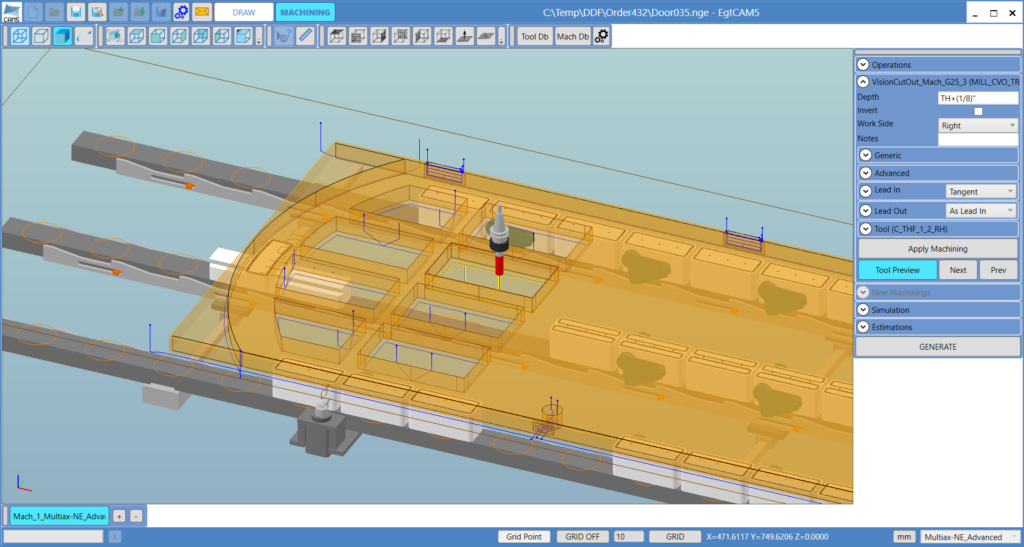

Manufactoring

- Automatic definition and positioning of raw parts

on the machine table with fixtures. - Definition of processing by type of hardware.

- Automatic machining selection depending on the

hardware used. - Customization of the processes to be applied, both

in automatic and manual mode. - Automatic calculation of processing on multiple

machines if necessary.

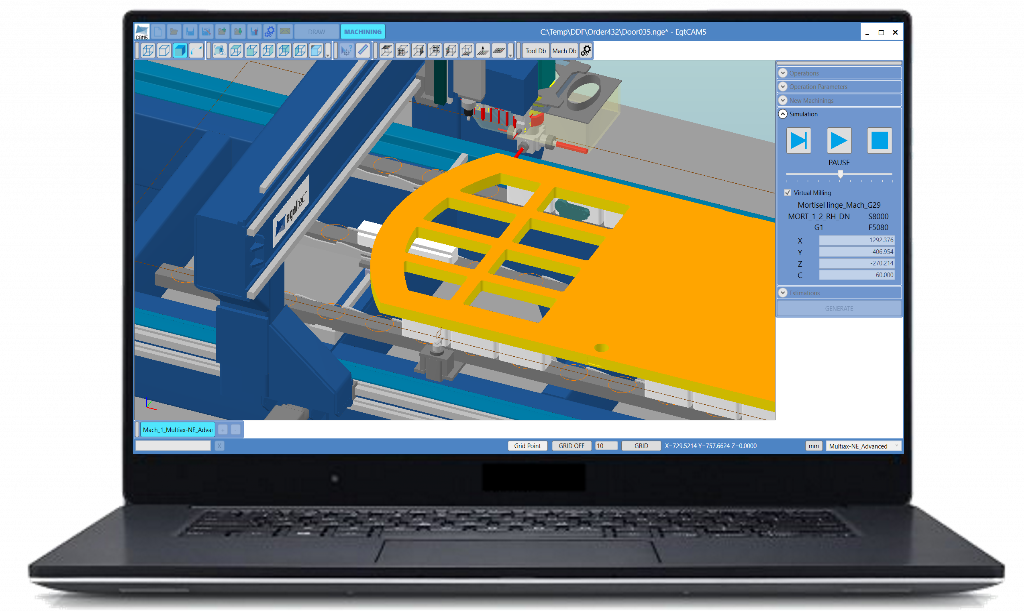

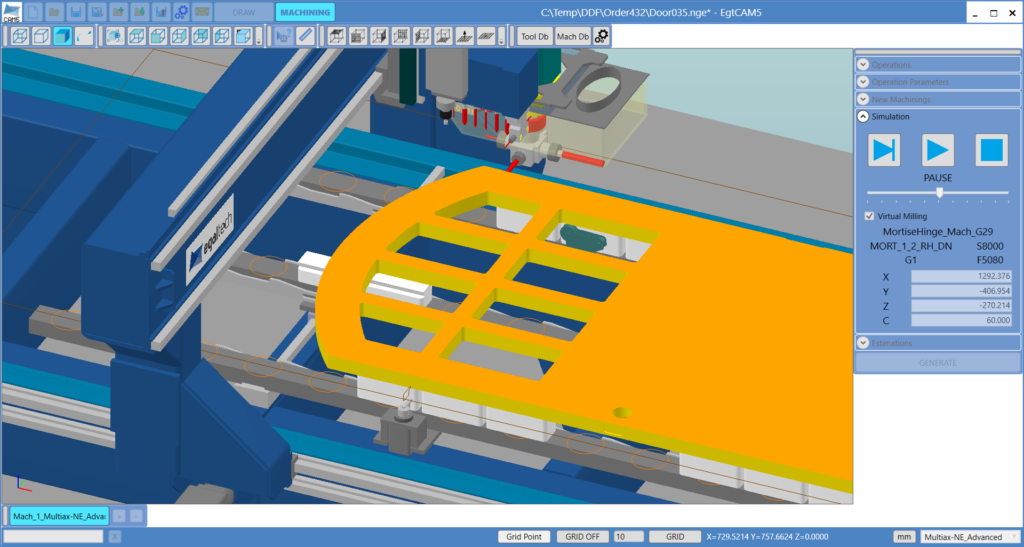

Simulation

- Specific machine model creation for machining simulation

that stays true to reality. - Virtual milling to verify the finished part appearance.

- Collision check between tools, part, machine fixed parts,

machine mobile parts. - Estimate of machining times and tool consumption.

Production management and Industry 4.0

- Management of raw materials and projects with

Barcode, QR code or RFID. - Automatic management of production queues.

- Integration between design, planning and workshop

departments, by sharing the same library of

hardware and projects. - Integration with the company management system,

via ddf file (door description file).

Request More Info

If you need more info about EgtCAM5, please fill up the form and we will contact you as soon as possible